The Inside Blowout Preventer (IBOP) is a check valve designed to control or prevent a backflow condition when the kelly or top drive is disconnected from the drill pipe. It controls the backflow through the inside of the drill pipe itself, preventing damage to the swivel, drilling hose, standpipe and circulation equipment.

During normal circulation of drilling fluids down the drill pipe, the valve remains open to permit the flow through it. A conical plug, or dart, minimizes the erosive action of the drilling fluid on the valve seat and assures a long lasting seal between the valve dart and valve seat

When the drill tool is lifted out of the hole, blowout could happen due to suction. In event of a blowout, the open position of the IBOP valve allows back flow, easing the installation process. Upon successful installation, the valve can be promptly closed with a relief rod to prevent further back flow. Fluid can then be pumped in from the surface to discharge the IBOP and drill string. The purpose of the blowout prevention can be achieved by the following generic steps: discharging the relief sub; regulation of fluid; commence pump circulation.

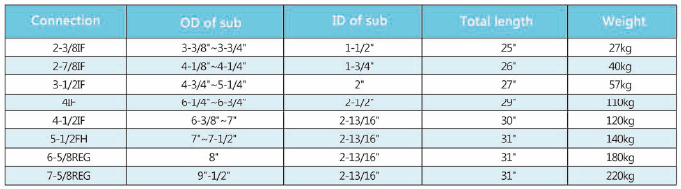

On inquiries and orders please specifiy :

n Connection Type

n Outside Diameter

n Inside Diameter

n Working Pressure

The Inside Blowout Preventer (IBOP) is a check valve designed to control or prevent a backflow condition when the kelly or top drive is disconnected from the drill pipe. It controls the backflow through the inside of the drill pipe itself, preventing damage to the swivel, drilling hose, standpipe and circulation equipment.

During normal circulation of drilling fluids down the drill pipe, the valve remains open to permit the flow through it. A conical plug, or dart, minimizes the erosive action of the drilling fluid on the valve seat and assures a long lasting seal between the valve dart and valve seat

When the drill tool is lifted out of the hole, blowout could happen due to suction. In event of a blowout, the open position of the IBOP valve allows back flow, easing the installation process. Upon successful installation, the valve can be promptly closed with a relief rod to prevent further back flow. Fluid can then be pumped in from the surface to discharge the IBOP and drill string. The purpose of the blowout prevention can be achieved by the following generic steps: discharging the relief sub; regulation of fluid; commence pump circulation.

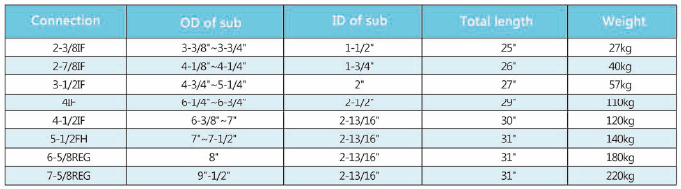

On inquiries and orders please specifiy :

n Connection Type

n Outside Diameter

n Inside Diameter

n Working Pressure